Maintenance is key to maximizing capacity utilization and achieving high Overall Equipment Efficiency (OEE). It is also a very difficult area to manage production – between putting out fires and completing changeovers on time, it is difficult to find the time and resources to modernize or make improvements.

With Operator Maintenance, you will see exactly which tasks devote the most Maintenance resources and efficiently organize the Continuous Improvement process in your production.

The Operator Maitenance solution works, among other things. At the Lantmännen Schulstad plant. Read below how it is being used, or check out the full video video of the implementation here.

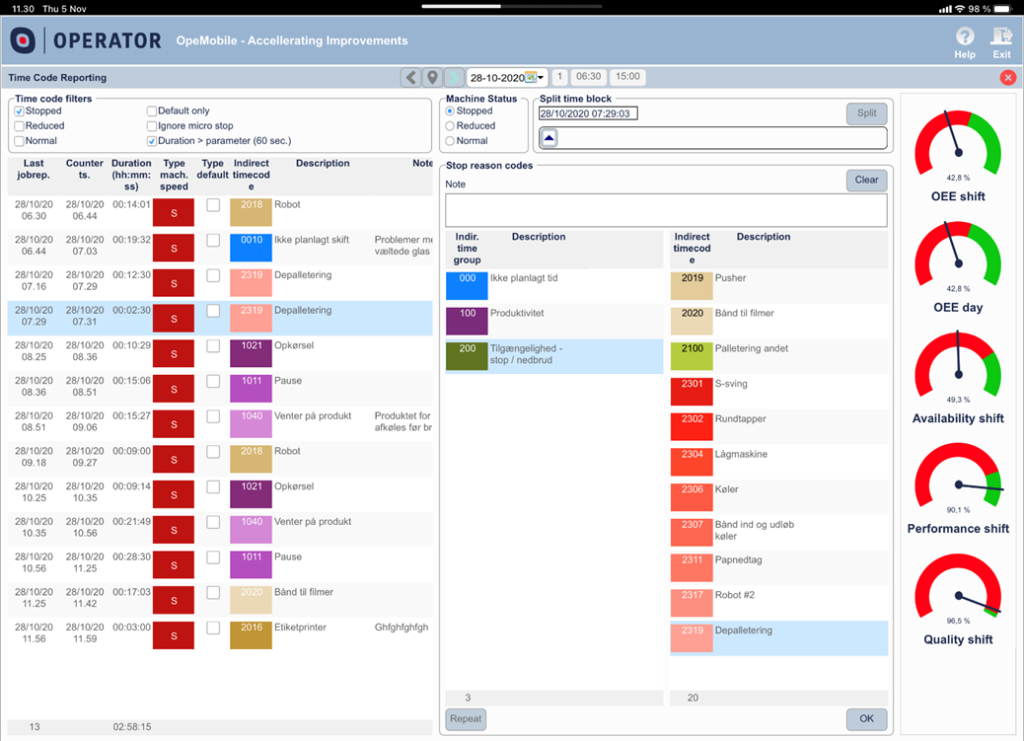

The goal of the Maintenance Department is to maximize uptime by minimizing machine breakdowns. Machine uptime is crucial to be able to deliver products. It can be said that machines are the heart of production. Line operators depend on a fully functional production line with minimal breakdowns that can lead to unscheduled overtime. The goal is to make it easier to analyze unplanned outages so that the maintenance department can take a deep dive into the data. The way it works is that the operator reports an unscheduled stop on the Operator OEE screen. The unscheduled stop is displayed in the maintenance department on a large screen. The first task of the maintenance department is to stop the bleeding and determine the root cause. Due to limited resources, the maintenance department performs Pareto analyses based on the given timeframe to address the most important cause of downtime, which affects working time. In this way, the maintenance department can address the problem in a systematic way.

Brian Andersen, Continuous Improvement Technician

Lantmännen Schulstad

What are the benefits of Operator Maintenance?

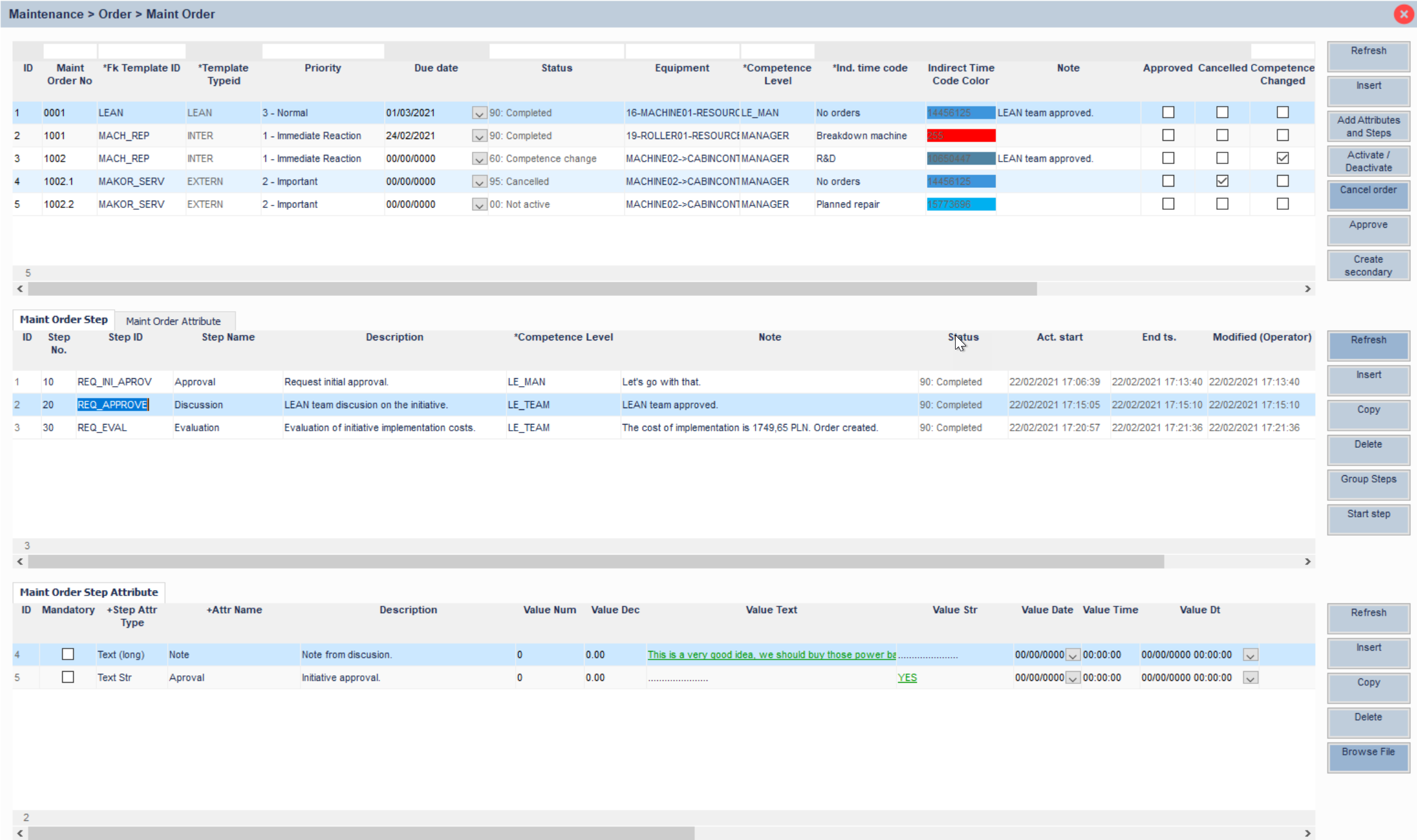

The Maintenance module of the Operator Platform, allows you to streamline communication between the shop floor staff and the Maintenance Department. Service tasks are carried out according to a defined process (workflow) , which significantly improves their execution and reduces machine downtime. The basic functionalities of the module are:

- Automatic or manual creation of service tasks containing the full information required by the Technician.

- Task list to monitor maintenance activities – their status, assigned people, planned and reported time, etc.

- Execution of a service order according to a defined workflow process, such as:

- Confirmation of acceptance of the order and start of work.

- Estimation of lead time.

- Completion of work.

- Notify the operator or foreman when the work is completed.

- Possibility to use the Operator mobile application to accept and complete tasks.

- The ability to use Manufacturing Intelligence dashboards and reports to inform, in near-real time, on problems in production.

This module can also be used to generate other types of notifications – based on any events monitored by the system (e.g. quantity produced, order status, checklist information, etc.).

Manufacturing Intelligence

The data collected by the Maintenance module of the Operator Platform will help increase the utilization of your production resources and reduce Maintenance costs.

It helps our customers build their competitive advantage.

This is possible using the Manufacturing Intelligence module that is part of the Operator Platform, which includes dozens of reports, dashboards and views that present data.

More recently, it has also been available with ACIP(Advanced Continuous Improvement Process), a mechanism for finding the most urgent areas for improvement based on artificial intelligence (AI).

Explore all the possibilities!

Operator Platform

Efficient production requires good cooperation between many areas, including, for example, production logistics, the quality department, planning or maintenance. See how Platform Operator supports our customers in streamlining production.

Let's talk

Our meetings with new clients are always free, without obligation. We also try to make them valuable. We will talk about the specifics of your production → this is key for us to present the right solution